C-Tech – Key Differentiators

C-Tech – Key Differentiators

C-Tech process is an advanced process in many ways compared to continuous, conventional or generic SBRs.

1.1 Biological Selector Zone:

The incorporation of a multi-cell biological Selector in the front – end of the System distinguishes it from all other technologies. The raw sewage/effluent enters the Selector Zone, where anoxic-mix conditions are maintained. Also, a part of the treated effluent along with activated sludge from the Aeration Zone is recycled here using Return Activated Sludge (RAS) Pump. As the microorganisms meet high BOD and low DO condition in the Selector Zone, natural selection of predominantly floc-forming microorganisms takes place. This is very effective in containing all of the known low F/M bulking microorganisms, which eliminates problems of sludge bulking and sludge foaming. This process ensures excellent settling characteristics of the biological sludge. SVI of treated effluent as less than 120 is achieved in all seasons. Also, due to the anoxic conditions in the Selector Zone, De-nitrification and Phosphorous removal occurs, in case Nitrogen and Phosphorous levels are high in the sewage/effluent. The figure below shows the experience with SVI developments in one of the plants in India.

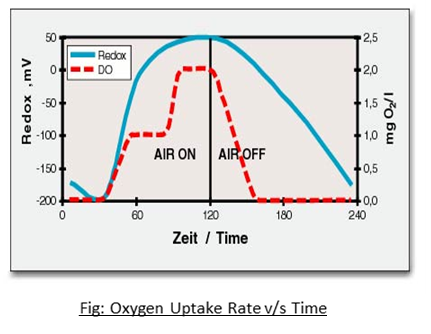

1.2 Oxygen Uptake Rate (OUR) Control:

The C-Tech process uses a measurement of Dissolved Oxygen (DO) levels in the Basin to provide a full-scale control of the activity level in the Aeration Basin. The DO concentration profile is automatically ramped to operate at slightly higher DO concentrations at the end of the Cycle. This feature prevents low dissolved oxygen type filaments from proliferating. Once DO level is measured in the Basin, the rate of drop in DO level is calibrated to know the actual Oxygen Uptake Rate (OUR) of the biomass. In this way, the metabolic activity of the biomass is measured within the actual Process Basin and is subsequently used as a control parameter to automatically regulate the duration of the aeration sequence and / or the rate of aeration. Aeration time can be altered

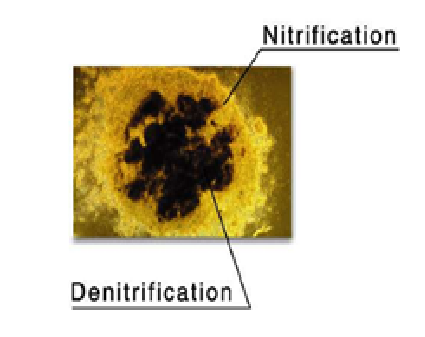

1.3 Simultaneous Nitrification and De-nitrification during Aeration Sequencing:

A balanced process is achieved and regulated by online-measuring of the specific oxygen uptake rate in the basin in such a way that the floc reaction profile allows for nitrification at the peripheral sections and de-nitrification at the inner parts of the floc as shown in Figure. Nitrate penetration is governed by its rate of diffusion which is of the order of ten times that of dissolved oxygen. Under aerated conditions there is typically no nitrate limitation in the interior zone of the floc. Sufficient carbon provision for de-nitrification is achieved through the carbon storage (biosorption) mechanism and the proportional DO demand regulation which minimizes the use of substrate carbon by oxic metabolization. The process can be regulated such that during the aeration phase there is nitrification and also de-nitrification taking place within the flocs. De-nitrification also takes place during settling phase. Rising of activated sludge due to nitrogen gas bubbling does not occur as during the relatively short time cycles only low concentrations of nitrate nitrogen have to be denitrified in each cycle.

1.4 Other Advantages:

- Absence of formal anoxic/anaerobic mixing sequences, hence less equipment.

- Reaction results obtained using shorter time cycles, hence less reactor volume.

- Simplified kinetic and metabolic filamentous sludge bulking control, hence deeper operating decant depth.

- Deeper decant depth and smart decanter operation, hence less footprint.

- Operates as a true fed batch reactor.

© Copyright 2018 by SFC Environmental Technologies Pvt. Ltd. All Rights Reserved | Designed & Developed by Crest IT Consulting