OREX Works

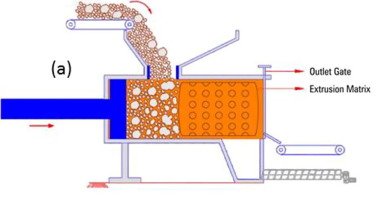

Step 1 : Feed Phase

The main piston loads the incoming mixed waste from the feeding hopper into the extrusion chamber with 8-16 mm aperture. The output gate is kept closed at this stage.

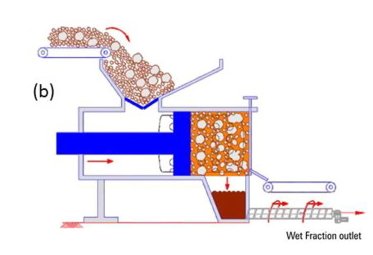

Step 2 : Compression Phase

The piston presses the waste at very high pressure against the closed gate. Due to the high pressure inside the extrusion chamber, the organic fraction is pulped and pushed out of the extrusion apertures along with the moisture contained within the cell mass. This wet pulped fraction is collected and conveyed out using a screw conveyor.

The dry inorganic fraction (paper, plastic, grit, cellulosic material etc.) remains inside the extrusion chamber.

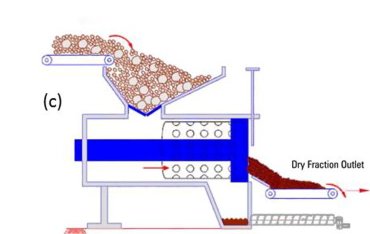

Step 3 : Expulsion Phase

The outlet gate opens and the piston pushes out the dry inorganic fraction from the extrusion chamber, on a conveyor belt.

The products obtained as a % of the input waste (on an average) are:

• Dryfraction: about30-40%

• Wet fraction: about 50-60%

© Copyright 2018 by SFC Environmental Technologies Pvt. Ltd. All Rights Reserved | Designed & Developed by Crest IT Consulting